Company Profile

We are a professional pet supplies industry and trade company located in Nanjing, the ancient capital of China during the Six Dynasties. We focus on designing and producing high-quality cat scratching pads such as sisal, polypropylene, bamboo fiber, and blended fabrics. The product backing uses environmentally friendly materials such as natural standard rubber, non-woven fabrics, and point-molded non-woven fabrics to ensure safety and durability.

Design and Customization Capabilities

The company has a professional design center and 8 professional R&D and design experts to provide customers with customized design, improvement and production services. We support OEM, ODM and OBM cooperation models to meet the diverse needs of customers.

Production Strength and Cost-effectiveness

Our modern plant area is 7000m², and the storage center is 2000m². It is equipped with advanced equipment such as sisal scraping machines, soft hemp machines, hemp sorting machines, drawing machines, spinning machines, UV machines, etc. to ensure efficient production and product quality, so that your cost is more advantageous in business operations.

Global Market Experience

We have rich experience in foreign trade exports, and our products are mainly sold to developed countries such as Europe, America, Australia, Japan and South Korea. With high cost-effectiveness and flexible customized services, we have won the trust and cooperation of customers around the world.

Production Process

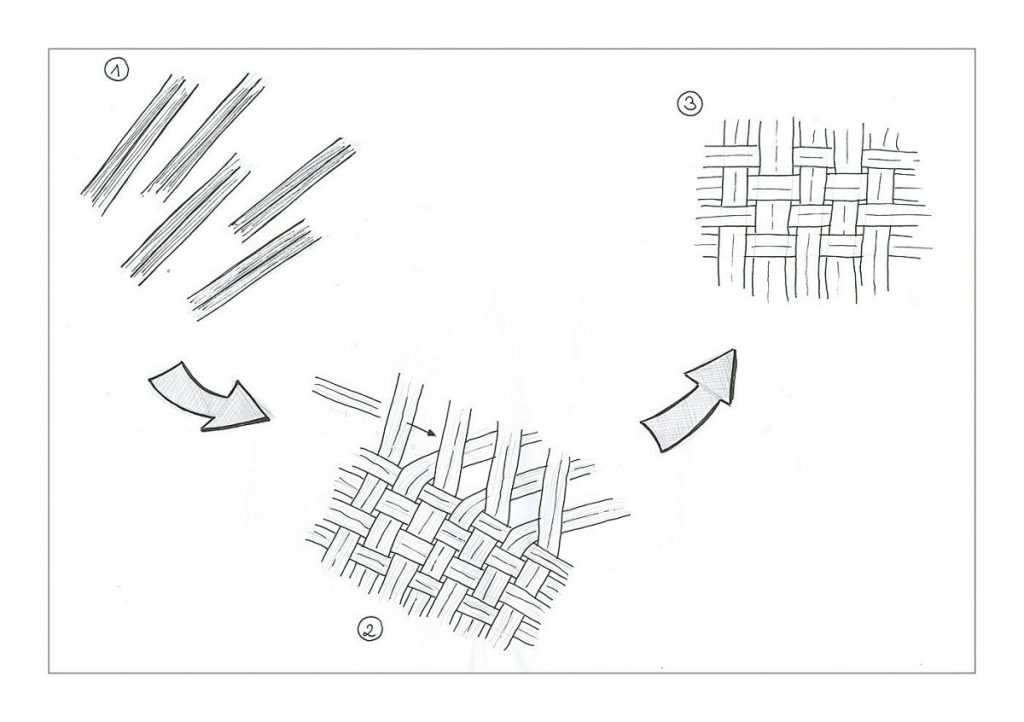

The process begins with sisal fiber separation and carding to refine strands. Fibers are spun into yarn, twisted into ropes, then woven into plain/twill fabric. Backing materials (non-woven or plastic) are laminated for stability. Precision-cut panels undergo edge finishing via serging, fabric binding, or hand-stitching. Optional hook-and-loop fasteners are sewn for mounting. Eco-friendly techniques ensure durability and pet safety, with quality controls at each stage.

1. Raw Material Processing

- Fiber Separation: Sisal fibers are mechanically separated and cleaned using a fiber separator, removing impurities and short fibers while retaining long strands.

- Fiber Alignment: A carding machine further aligns fibers into parallel arrangements and reduces residual impurities.

2. Rope Preparation

- Blending: Fibers are merged into uniform strands via a blending machine.

- Spinning: Strands are twisted into yarn using a ring spinning frame.

- Twisting: A double twister reinforces yarn strength through secondary twisting, forming durable sisal ropes.

3. Weaving Process

- Fabric Weaving: Ropes are woven into plain or twill-patterned fabric on a loom, followed by manual inspection to repair defects.

4. Backing & Cutting

- Backing Application: The fabric is laminated with non-woven fabric (via dot embossing) or plastic film to enhance stability.

- Precision Cutting: Computer-guided cutting tools shape the fabric into designated sizes with clean edges.

5. Finishing

- Edge Binding: Edges are finished with machine-applied fabric trim, serging, or hand-stitched wrapping.

- Hook-and-Loop Attachment: Sewing machines affix hook-and-loop fasteners for secure mounting.

Important Links

Contact Us

Nanjing Yiben Culture Technology Co., Ltd.

Email: busniess@yiscratch.com

Whatsup: +86 15850601088

Welcome to click the “Contact Now” button on the right so we can contact you faster.